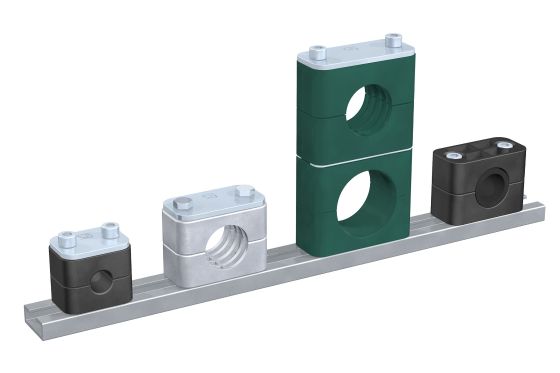

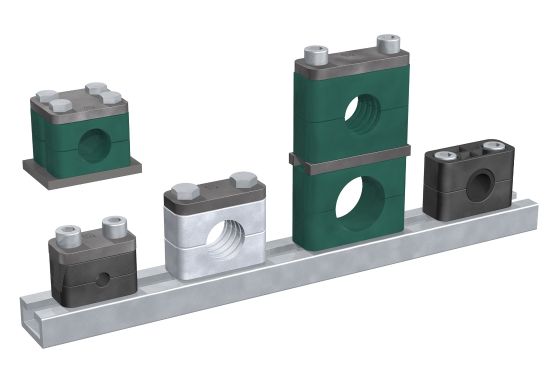

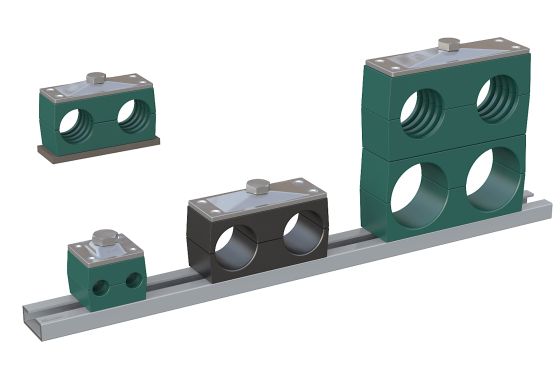

Mounting rails type TS are used for quick and easy installation of Original STAUFF Clamps in the Standard Series and Twin Series according to DIN 3015 (Parts 1 and 3), if several pipe, tube, hose or cable lines should be fixed in parallel:

Instead of fixing several clamps separately, they are inserted into a mounting rail, slid into the correct position and the rail nuts are tightened.

The mounting rail itself must be welded on by the user beforehand, either spot-welded or over the entire length. Occasionally, the rail is drilled first and then bolted to the system. Both methods are comparatively labor-intensive.

STAUFF has found an alternative solution for this: Fastening adaptors now make assembly much easier. Why their use also reduces the risk of corrosion is explained below in this blog post.

Adaptor for Easy Installation of Mounting Rails

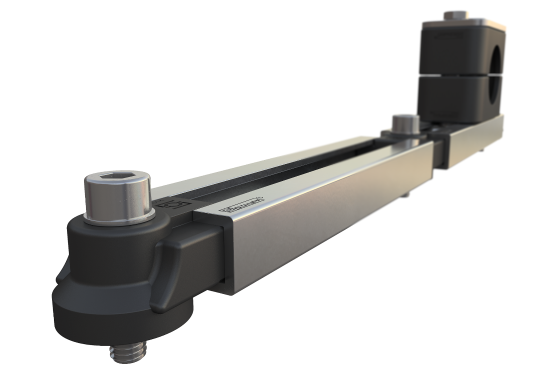

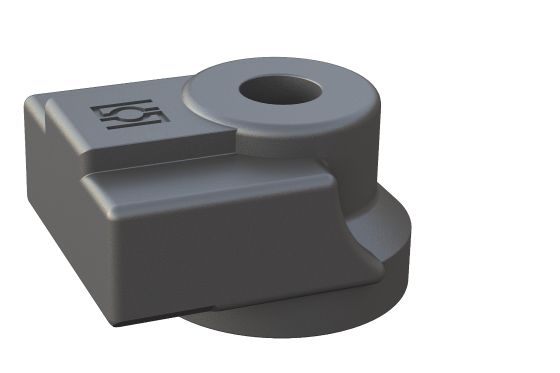

Plastic mounting adapters with holes for M6 bolts are now available in the STAUFF Online Shop for mounting rails type TS-14 with an overall height of 1/2 inch.

They are pressed into both ends of the mounting rail and easily screwed to the system. The mounting rail itself no longer needs to be drilled or welded on to ensure stable fixing of pipe, tube, hose and cable clamps with the appropriate rail nuts type SM.

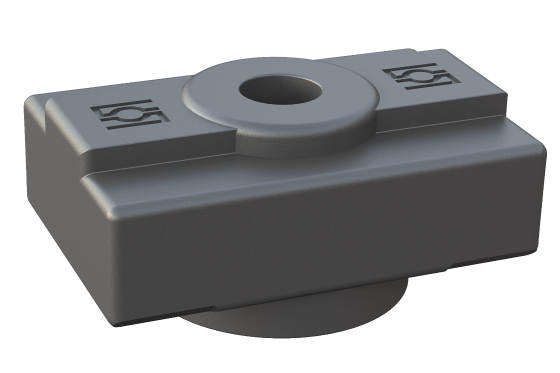

In addition to the end pieces, there are also intermediate pieces with which two mounting rails can be connected.

Reduced Risk of Corrosion

With the adaptors, the STAUFF developers have solved another problem: With conventional mounting methods, the mounting rails are positioned directly on the system, i.e. metal on metal. In addition to dirt, moisture also collects quickly here, which can lead to corrosion. Even the painting that is common in practice only protects against this to a limited extent, as the paint often does not reach the crucial points under the rails that are only spot-welded or bolted on.

The obvious alternative, a complete weld seam around the entire mounting rails, is often not sensible from an economic point of view and can lead to material distortion.

STAUFF mounting rail adaptors simplify installation, shorten its duration and lead to a permanent reduction in the risk of corrosion. This is because there is a minimum distance of 2 mm between the mounting rail and the system. This aspect is not only important when the system comes into direct contact with water, but also in applications with strong temperature fluctuations or high humidity.

DIN 3015 Clamps in the STAUFF Online Shop

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog